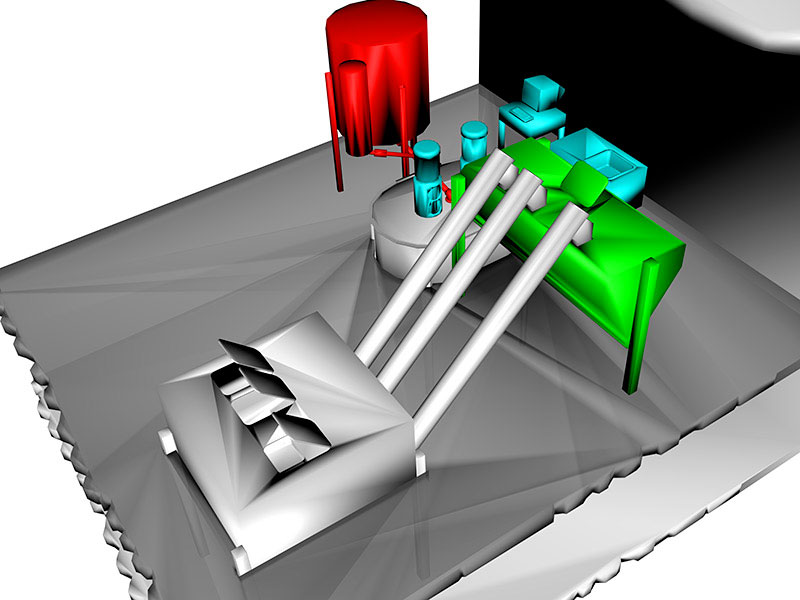

Automated Mixing Systems

We specialize in Automation-like Mixing-on-Demand Adhesive Solutions

Our equipment monitors how much glue is being made, what components are needed and in what quantity, and also controls the tank-to-tank pumping to ensure no accidental loss of component or product. The only task for the operators is to ensure that supply materials are available (water, resin, caustic (liquids), and soda ash, wheat or other dry extenders (corn cob, coconut husks, etc). Warning indicators can allow operators notice when materials are getting low. Man-hours are minimized for your glue mixing operation, and the increased accuracy will allow full yields with minimized waste.

Automated batches can be programed to process from the first charge through the final pump out. Automating the glue mixing process provides the consistency of reproducing the same adhesive each time for performance without variation.

The systems are generally custom designed to meet your specific adhesive requirements, with the level of automation based on your needs. Systems from small volume mixing on demand, or meeting specific glue pot life limitations, to large volumes mixing. The process can be automated from off sight monitoring, to recorded collection of data, or basic PC processing.

We like working with our customers to solve their adhesive processing challenges. Innovation with a system that fits your specific needs. Holte mixers are capable of making smooth lump free glue in any viscosity range.

Consulting

Glue Mixer Consulting Services Our Team has experience [...]